Expanded polystyrene recycling

Businesses handling large volumes of polystyrene have the perfect solution to shred, compact and recycle polystyrene. You will save on disposal costs and earn money from selling the materials afterwards.

Polystyrene recycling and sustainable waste management policies are essential for saving both money and space with this material.

Businesses handling large volumes of polystyrene have the perfect solution to shred, compact and recycle polystyrene. You will save on disposal costs and earn money from selling the materials afterwards.

Expanded polystyrene (also called Styrofoam, EPS etc.) is extremely useful for packaging in many industries.

Polystyrene is a versatile plastic polymer made from styrene, a monomer derived from petroleum and natural gas byproducts. It is widely used due to its ease of production, cost-effectiveness, and beneficial material properties. This thermoplastic polymer comes in two primary forms: solid and foam.

Polystyrene’s versatility is one of its most significant advantages. It can be easily molded and fabricated into a wide range of products, from rigid and clear plastic containers to lightweight and insulating foam. The material’s applications span across several industries, including packaging, construction, consumer goods, electronics, and medical supplies.

For instance, in packaging, polystyrene is used for disposable coffee cups, plastic food containers, lids, bottles, and trays. Its insulating properties make it ideal for use in building insulation and protective packaging for fragile items during shipping.

Polystyrene is relatively inexpensive to produce, making it an attractive material for manufacturers. The production process is efficient, allowing for high-volume manufacturing with consistent quality. This cost advantage translates to lower prices for end-users and consumers, which is particularly beneficial in the packaging industry where cost margins are tight.

The physical properties of polystyrene make it highly desirable for various applications. It is lightweight yet strong, providing sufficient protection for packaged goods without adding significant weight. Its rigidity and clarity make it suitable for products that require a clear view of the contents, such as food containers and display cases. Additionally, expanded polystyrene (EPS) foam is an excellent insulator, used in both thermal and sound insulation applications.

One of the most significant challenges associated with polystyrene is its environmental impact. Polystyrene products, particularly single-use items, contribute to the growing problem of plastic pollution. They are not biodegradable, persisting in the environment for hundreds of years.

This persistence leads to the accumulation of polystyrene waste in landfills and natural ecosystems, where it can break down into smaller microplastics, posing a threat to wildlife and marine life.

Recycling polystyrene is not as straightforward as recycling other plastics. Its lightweight and bulky nature make transportation to recycling facilities costly and inefficient. Furthermore, the market for recycled polystyrene is limited, reducing the economic incentive for recycling programs. Contamination of polystyrene with food waste and other materials also complicates the recycling process, making it more challenging to produce high-quality recycled products.

There are health concerns associated with the production and use of polystyrene. Styrene, the monomer used to produce polystyrene, is a potential human carcinogen. Workers in the production facilities and consumers who use polystyrene products may be exposed to styrene, albeit at low levels. Additionally, there is ongoing research into the potential health impacts of polystyrene food containers, particularly when they are used to hold hot or acidic foods, which may cause the material to leach chemicals.

Environmental responsibility:

Reduces landfill and ocean waste, protects the environment, and boosts eco-friendly reputation, fostering consumer trust.

Economic benefits:

Initial costs lead to long-term savings, revenue from recycled materials, and lower waste disposal costs.

Sustainable branding:

Aligns with consumer values, enhancing brand image and market positioning while opening new marketing opportunities.

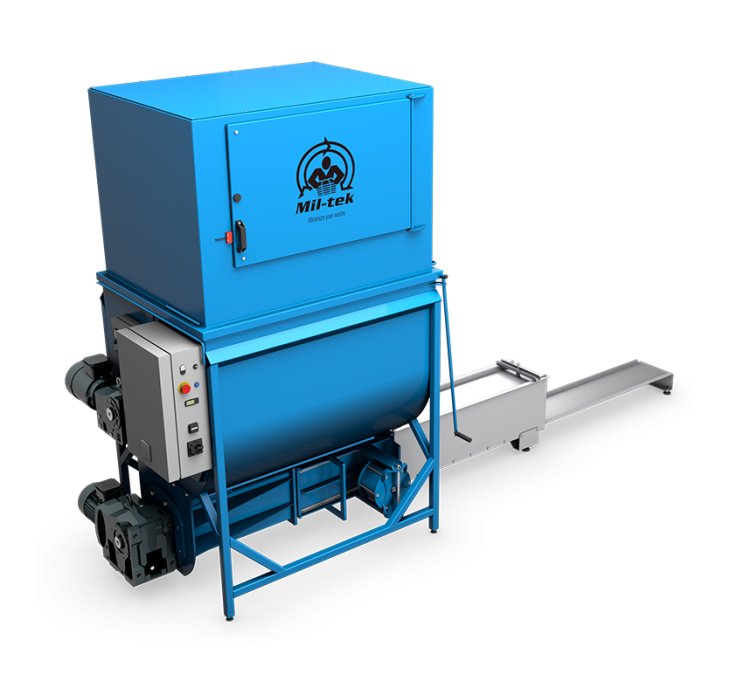

Businesses looking to recycle styro can benefit from solutions offered by Mil-tek. These innovative solutions streamline the recycling process, making it efficient and cost-effective.

Mil-tek provides equipment designed to reduce the volume of polystyrene waste, transforming it into manageable forms that are easier to store and transport. This not only helps businesses save space but also cuts down on waste disposal costs.

Complete the form below and find out how your business can start earning money and become more sustainable by recycling polystyrene waste.