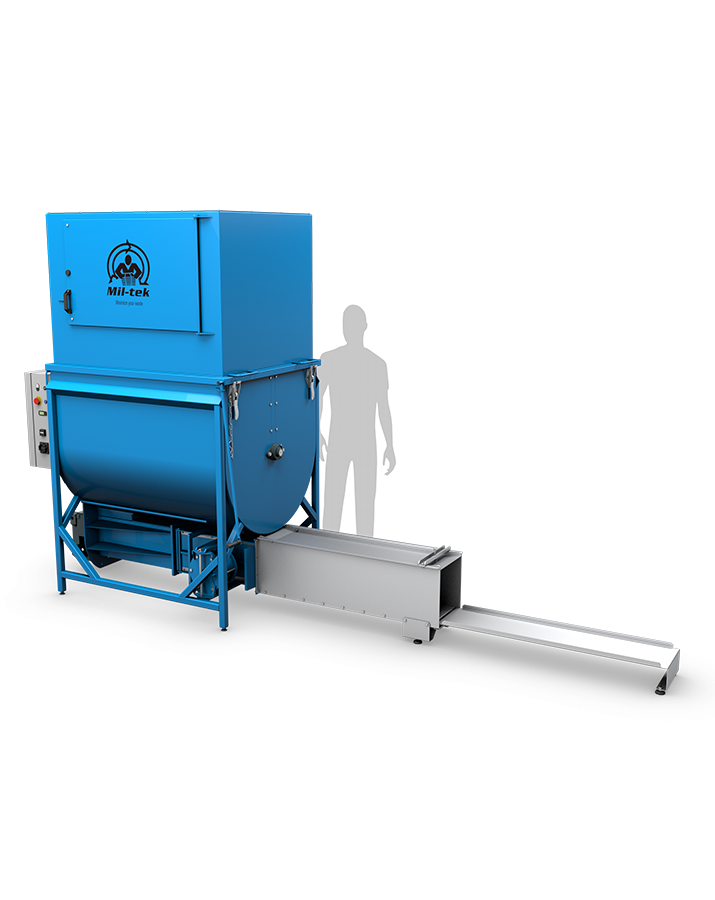

The Mil-tek EPS 2000 Polystyrene Compactor is ideally suited for compacting EPS6, the most prevalent form of Expanded Polystyrene (EPS, Styrofoam, airpop).Numerous industries, such as electronics manufacturers, distributors, fishing and food processing, use EPS6 for packaging; it is an ideal material for protecting products and components during transport.

The Mil-tek EPS 2000 Polystyrene Compactor pulverizes and reforms EPS6 into a briquette that can be sold and recycled into plastic components such as electronic devices, toys, DVD cases, etc. By processing your EPS6 with a Mil-tek EPS 2000 Polystyrene Compactor, you not only save money compared to sending it to a landfill in mass, but you also generate revenue for your business.

A Mil-tek consultant will assist you in locating a customer for your compacted EPS6 among regional or national recyclers.