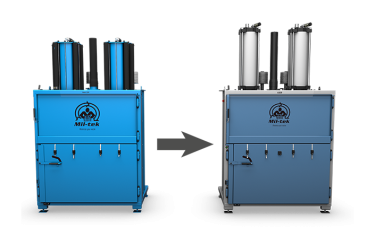

2509 Plastic Cardboard Baler

The Mil-tek 2509 baler is ideal for coping with large quantities of cardboard and/or plastic, especially when space is limited. Despite its tiny footprint, the 2509 is capable of producing 400 kg bales.

- Manages large volumes efficiently and swiftly

- Automatic bale-out system

- Widespread compression chamber

- New EN16500 security functions

- Pressing cycle acceleration and a bale-out indicator

- Enhanced safety features and securing mechanisms