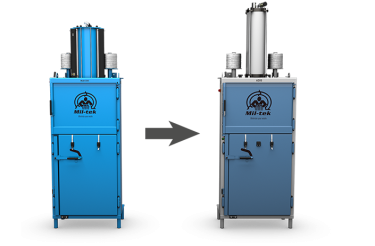

The Mil-tek 2205

The Mil-tek 2205, an update to the 205TS, is completely compliant with EN16500 safety standards. The 2205 baler has a compact footprint of approximately 0.29 square meters and a long vertical pressing chamber. This means that the 2205 baler can produce a bale that is nearly twice as large as a model 2102 while occupying a comparable amount of floor space.

The operational and safety features of the EN16500-compliant machines make them not only our safest machines ever, but also our quickest: the 2205 has a complete pressing cycle of approximately 7 seconds.

The Mil-tek 2205 baler, like all EN16500-compliant devices, is powered solely by compressed air. This indicates that the pneumatic harvester uses significantly less energy than its hydraulic counterpart. The 2205 baler features patented ECO-Drive technology that balances the amount of pressure required for each stroke and applies constant compacting pressure without increasing energy consumption.