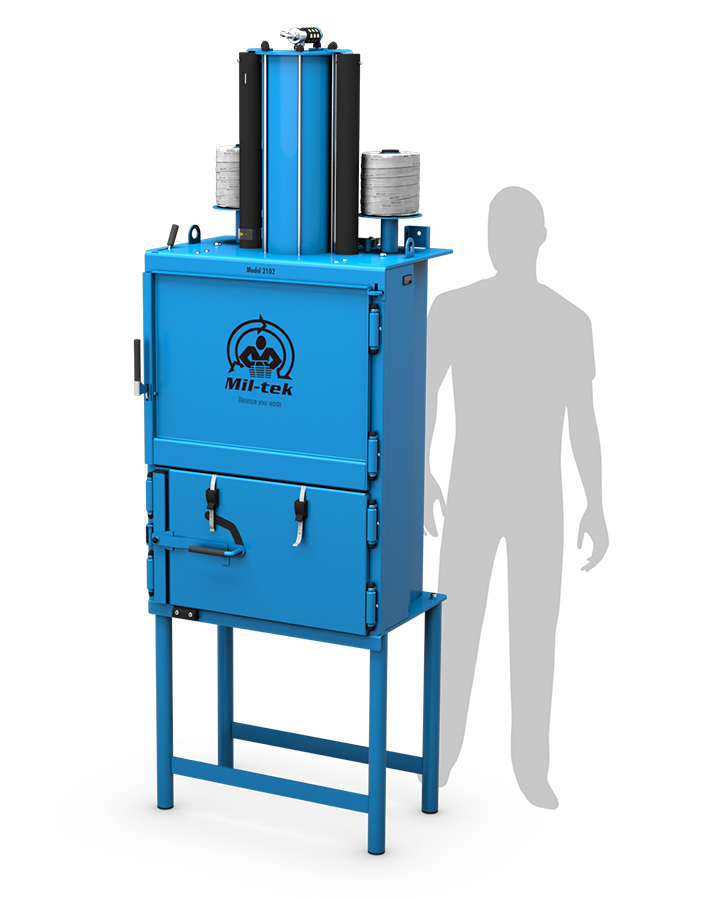

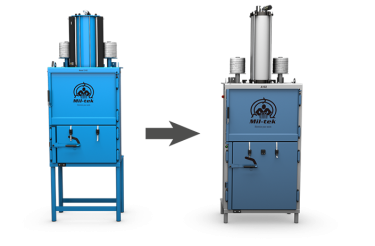

Flexible solution

The Mil-tek 2102 Baler is renowned for its adaptability, as it is designed to accommodate in even the smallest spaces where efficient waste compaction is required to maintain a safe and clean working environment.The safety and operational features of the Mil-tek 2102 make it an ergonomic, simple, clean, and safe to operate machine that can be placed close to the source of waste.

Mil-tech devices are designed to be operated by virtually anyone. Simply place your material inside, close the door, and pull the lever; the machine will do the rest. The 2102 has a striking cycle that is between 10 and 20 seconds. The Mil-tek 2102 is propelled by compressed air from either an existing air line or a Mil-tek-supplied compressor. This indicates that the baler is devoid of both electrical and hydraulic components, reducing the risk of fire and eradicating the possibility of oil contamination entirely.